Your product is only as profitable as the way it’s developed.

In product development, the biggest savings aren’t made at the end, they’re built in from the start.

After years of refining our approach, we’ve identified the most effective ways to control cost during design and development. Now you can apply them to your own projects, one step at a time.

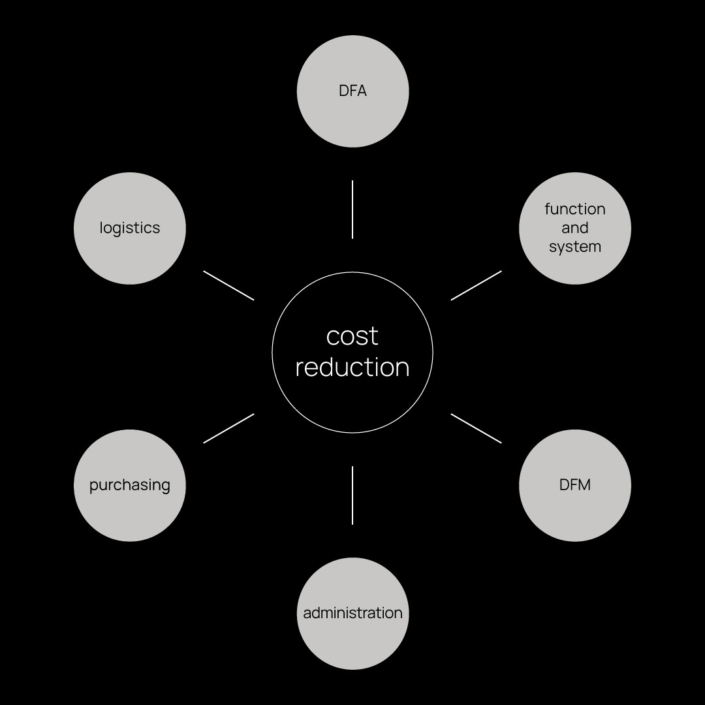

Each week, you’ll unlock a new branch of our Cost Reduction Map, a tool based on decades of real project experience.

One map.

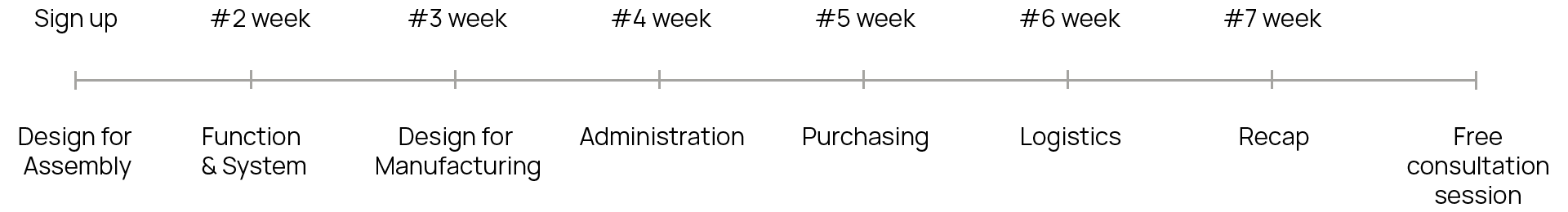

Seven weeks.

Real savings.

When you sign up, you’ll receive:

- Email 1 (Instant): Our first strategy to reduce costs, Design for Assembly.

- Emails 2–6: One new strategy each week, with practical examples from real projects:

-> Function & System

-> Design for Manufacturing

-> Administration

-> Purchasing

-> Logistics - Recap Email: Full map + Invitation for a free consultation session with one of our designers to apply the map to your own product.

“A big part of cost reduction is thinking about it from day one. Small design choices early can save thousands later on.”

Eric van der Voort

Senior Designer Producibility and Assembly

“The cheapest design is not always the smartest. Sometimes a slightly more expensive part can save money in assembly, testing, and logistics.”

Kasper van der Wiel

Specialist Designer Functionality and System

“We look at the entire product lifecycle, not just the production phase. True cost control means considering use, maintenance, and end-of-life from the start.”

Stefan Klocke

Designer Producibility and Assembly