End-to-end product design and development for the industrial sector

Complex machinery asks for more than just technical performance, it requires reliability, usability, and compliance from the start. MMID provides industrial product design and development as a full-service partner, guiding companies from an early concept through to verified, production-ready solutions. As experienced industrial product design and development consultants, we bring together mechanical, electronic, and software expertise to create robust, user-focused equipment. Whether it’s precision tools for manufacturing, automated systems for logistics, or advanced industrial machinery, our multidisciplinary approach ensures every design is innovative, user friendly, and built to perform in demanding environments.

What kind of industrial equipment and machinery do we develop?

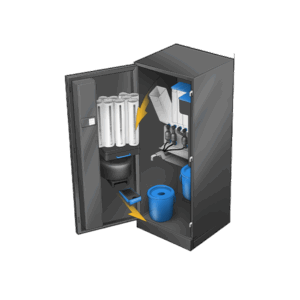

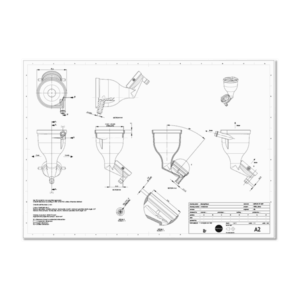

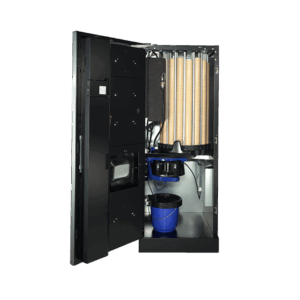

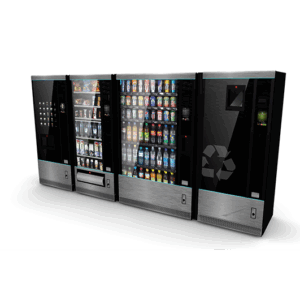

At MMID, we support clients with end-to-end industrial product development and design, delivering equipment that is robust, reliable, and ready for the factory floor. Our work spans a wide range of applications, from semiconductor manufacturing equipment design to logistics machinery and industrial automation systems. We also bring expertise in industrial cleaning equipment, production line equipment, and industrial robotics systems, helping clients innovate in sectors where precision and uptime are critical.

Examples of our contributions include:

-> Semiconductor manufacturing systems – designed for precision, cleanroom compliance, and operator usability.

-> Vision-based logistics machinery – advanced inspection and automation solutions that streamline complex processes.

-> Industrial cleaning equipment – durable, ergonomic systems that improve efficiency while reducing operator strain.

Each project demonstrates how our multidisciplinary approach combining mechanical, electronic, and software engineering with user-centered design, results in products that meet regulatory demands and deliver measurable business value.

MMID’s experience and expertise in industrial sectors

As a trusted industrial product design and development company, MMID has more than 30 years of experience helping global manufacturers bring complex machinery and systems to market. Our multidisciplinary teams combine mechanical, electronic, and software expertise to create solutions that are not only technically advanced but also user-friendly and compliant with industry regulations.

By partnering with us, companies benefit from:

-> Proven reliability through our structured LUCID process.

-> Faster time-to-market with reduced development risks.

-> Access to a partner experienced across semiconductors, logistics, and automation.

Our track record includes collaborations with leading industrial clients, demonstrating our ability to deliver robust, compliant solutions that drive long-term business value.

Our safety product development process

Developing complex machinery requires a structured, transparent, and aligned path. With our industrial equipment development process, MMID applies the LUCID method to guide companies from idea to validated product—ensuring usability, reliability, and performance at every stage of the industrial product lifecycle.

1. Vision

We start by identifying operational goals and technical challenges, while mapping the needs of both expert and non-expert operators. Our teams explore relevant technologies, from automation and robotics to HMIs and sensors, and align the business case with usability and performance goals. This ensures a clear, strategic start of industrial product development.

2. Definition

We explore multiple design directions, visualizing and testing early ideas with rapid prototyping and user feedback. Critical components such as robotics, vision systems, or interfaces are validated for feasibility, regulatory requirements, cost, and scalability. Through early risk analysis, we identify potential weak points and bring stakeholders together around the most promising concept for industrial use.

3. Specification

Mechanical, electrical, and software interfaces are defined to enable seamless system integration. Our engineers develop a detailed product architecture tailored for industrial equipment design, ensuring each subsystem functions reliably within the complete machinery. This stage provides the technical blueprint for a robust and manufacturable solution.

4. Verification

We build functional prototypes for lab and field testing, putting designs through environmental, mechanical, and electrical trials. Usability testing with real or simulated operators ensures the equipment performs as intended under industrial conditions. This rigorous phase validates that the product is safe, reliable, and operator-friendly.

5. Optimization

Feedback from verification guides targeted refinements. We improve assembly, reduce cost, and strengthen durability, preparing the product for efficient manufacturing while preserving its core functionality and safety-critical features.

6. Realisation

Production samples and tooling are finalized, while documentation is completed to ensure manufacturing readiness. Compliance validation confirms that the product and processes meet international standards, giving clients confidence to move forward at scale.

7. Implementation

The industrial machinery development journey concludes with validated products entering market use. Regulatory files are submitted or approved, and the equipment is launched with full production support. Post-market surveillance ensures continued reliability and compliance across the product’s lifecycle.

Case studies: innovating industrial equipment and machinery

MMID’s role in industrial product design and development is best demonstrated through the projects we deliver. From semiconductor manufacturing equipment design to industrial automation systems and production line machinery, we help clients transform complex challenges into reliable, user-centered solutions.

FAQ about industrial product development

What is industrial product development?

It is the process of designing and engineering complex machinery and equipment for industrial use. Unlike consumer products, industrial systems must combine precision, durability, usability, and compliance to perform reliably in demanding environments.

What are the phases of developing an industrial product?

At MMID, we follow our structured LUCID process: Vision, Definition, Specification, Verification, Optimization, Realisation, and Implementation. This ensures a clear path from concept to validated, production-ready equipment.

What services do you offer in the making of industrial equipment and machinery?

We provide end-to-end support, including concept development, prototyping, usability testing, mechatronics, electronics integration, producibility engineering, and compliance validation, tailored to industrial equipment design and development.

How do you ensure industrial machinery is safe and reliable?

We conduct extensive lab and field testing, covering mechanical strength, environmental conditions, electrical safety, and operator usability. Early risk analyses help us identify and resolve weak points before products reach production.

Do you work with specialized sectors like semiconductors or logistics?

Yes. We have experience in semiconductor manufacturing equipment design, logistics automation systems, and other highly technical industries where reliability, precision, and uptime are business-critical.

Manufacture your industrial equipment and machinery with MMID

Looking for industrial product design and development consultants to bring your next machine to market? MMID combines a proven process that reduces risks, accelerates time-to-market, and ensures regulatory compliance!