Project overview

Kampmann, an established company in the ventilation industry, came to us for a revamp of a product that had been on the market for 20 years—this was a ventilation unit used for environmental control of commercial spaces. Though their product had been successful, they were looking to move from a complex sheet metal design to a simpler and more cost-effective Expanded Polypropylene (EPP) housing. There was also a sustainable/user-focused desire to add the functionality of being able to direct air based on the heating/cooling functionality.

Design Challenges

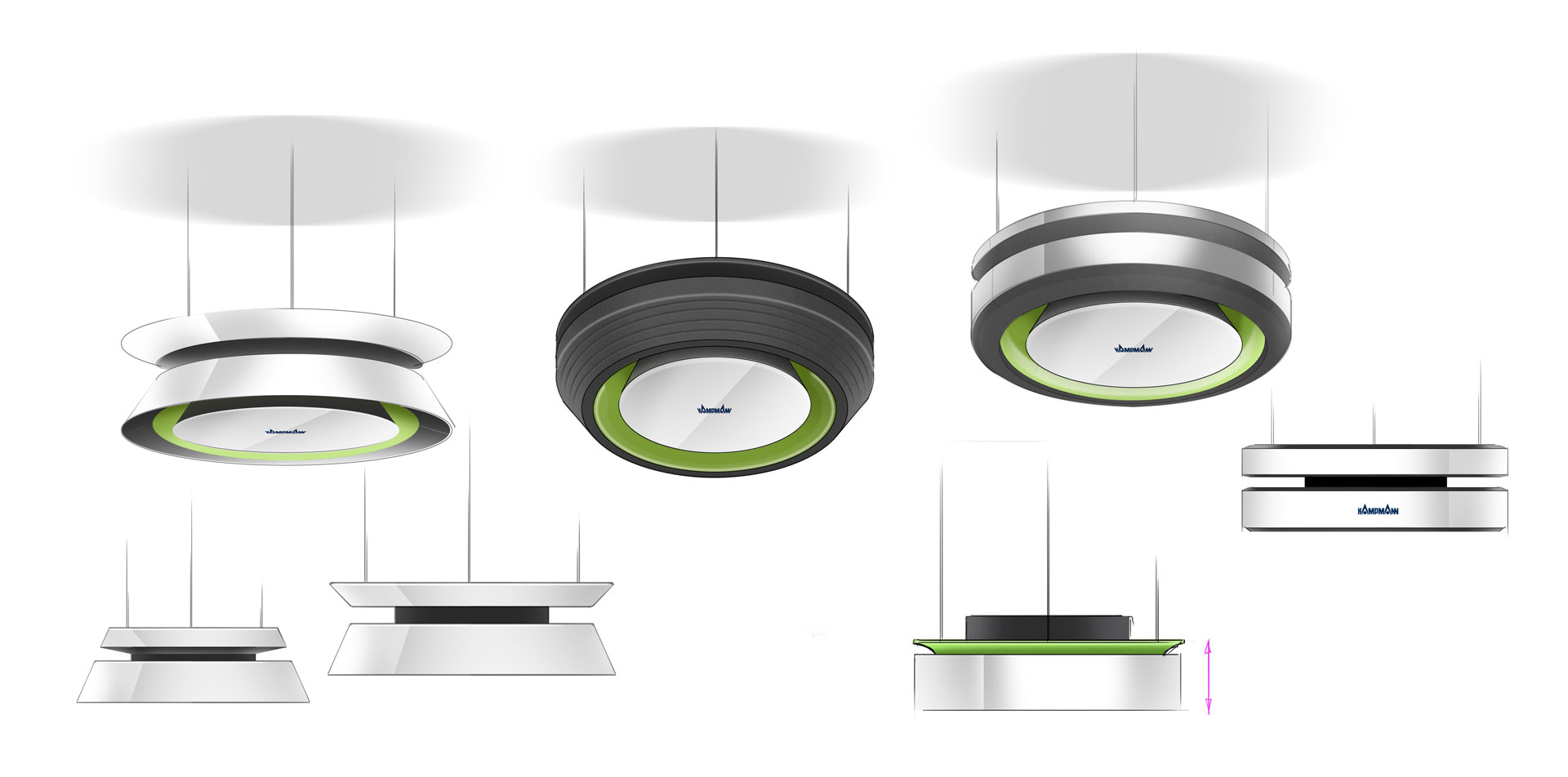

The primary goals were cost reduction, simplified assembly, and an improved product design. Improvements in ventilation, added functionality in air redirection, and air flow optimization for enhanced efficiency were also critical factors to the design process. There was also a desire to create a more updated, modern design which included the possibility for customizations for individual clients so that the device could match their branding.

Approaching the Challenge

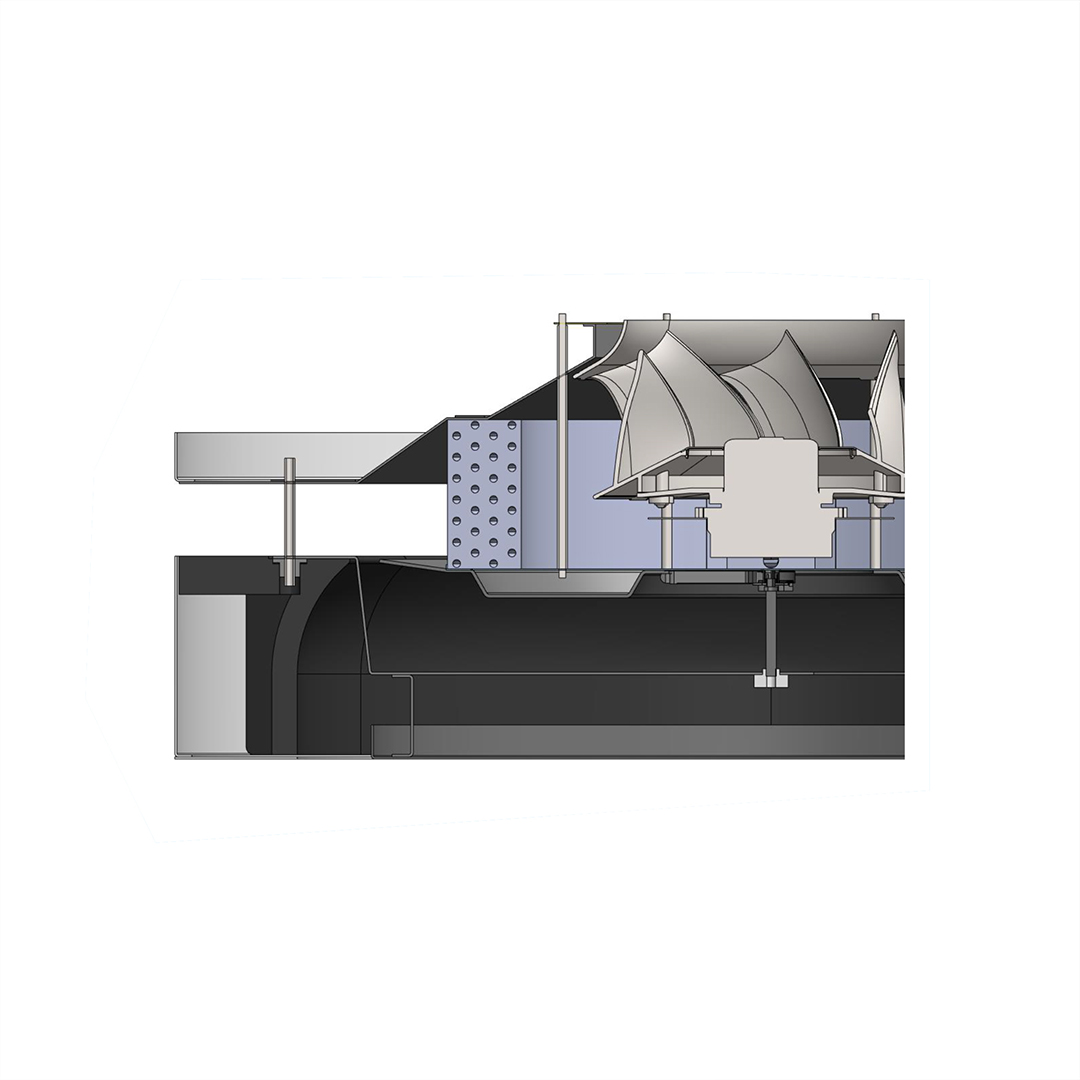

Our approach involved analyzing the existing concept, focusing on essential elements such as the fan and the added functionality of air redirection. We kept the functional core and simplified structural components where we could by using an EPP housing. This streamlined assembly, reduced part costs, and reduced the overall volume of the product while keeping and even improving the existing functionality.

Energy Efficiency and Sustainability

Even though EPP isn’t from a sustainable source, it is recyclable, and its insulating properties significantly improved the product’s efficiency and minimized the number of parts that needed to be made in production. Efficiency was also helped by improvements to airflow in the design. These efficiency savings can really add up if this device is operating for 5-20 years, all the while providing a noticeably more comfortable environment for users.

User Experience

The aesthetic design was also improved to blend more seamlessly to a store environment. For instance, supermarket ceilings are already very crowded and technical, so the device was made not to stand out. The improved functionality of having directed air also improved the experience of shoppers, as they witness the direct effects of heating/cooling without first having to circulate throughout the building. Thinking also about the user experience of repairmen, we ensured the dis-assembly was straightforward to make their job easier.

Collaboration with Kampmann

We knew that Kampmann was more conservative when it came to aesthetics, so when we presented new ideas, we presented a range of design options. These options ranged from something similar to what they have now, all the way to what their device could look like in 20 years. By using this approach, we were able to align on a concept that pushed the envelope and showed innovation, but still matched how Kampmann wanted to be perceived in the market as a conservative, reliable brand. In the end, the product closely resembled the initial sketch agreed upon—this demonstrates a successful collaboration and alignment.

Conclusion

The redesigned Kampmann ventilation unit is a great example of a successful collaboration, addressing technical challenges, enhancing energy efficiency, and delivering an improved user experience. This case study shows the positive outcomes that you can achieve through integrated development and great collaboration.

Our work

It’s the result that counts. Check out a part of our construction segment portfolio, showing a variety of successfully introduced ventilation and building products.