Take the First Step Toward Excellence in Design!

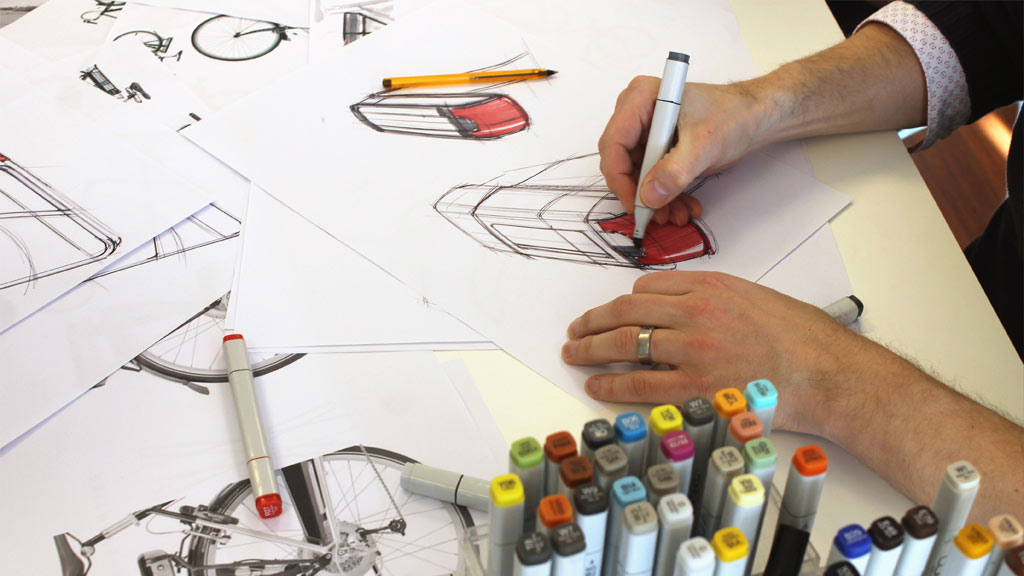

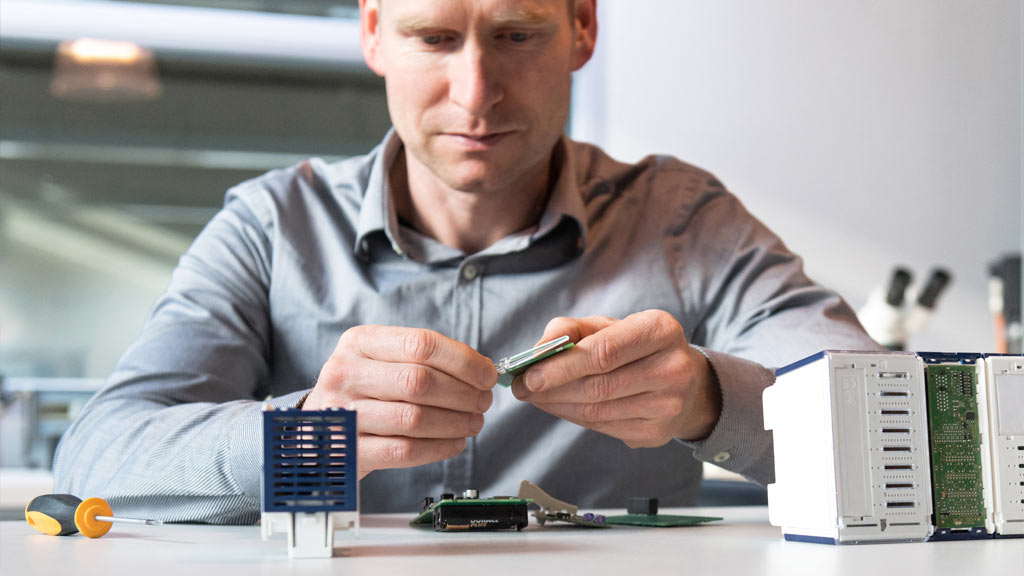

Schedule a meeting with our expert designers

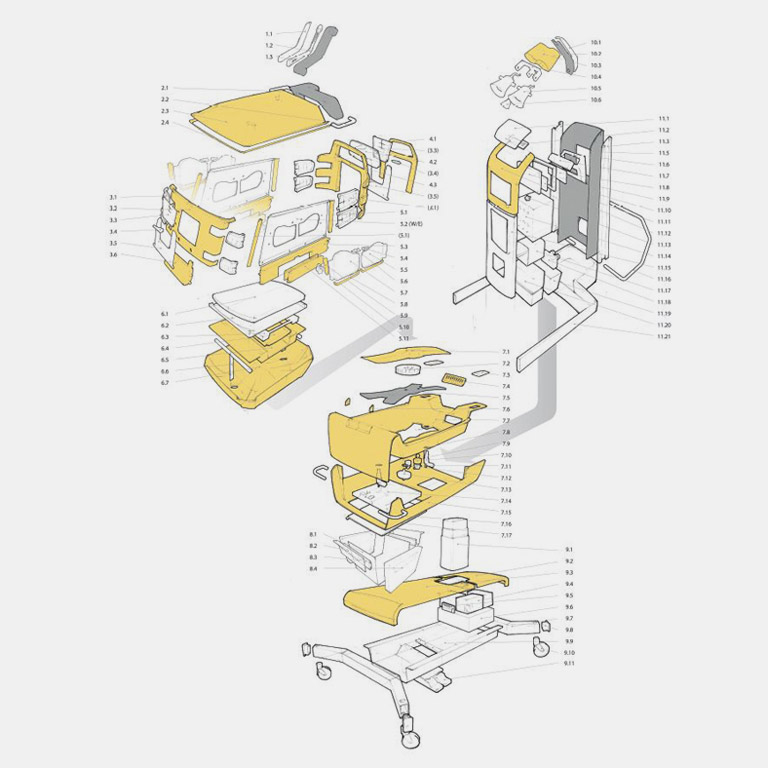

-> Receive personalized design solutions tailored for your project

-> Gain actionable insights for immediate implementation

-> Discover our proven methodologies and how they can work for you