Reducing cost at every stage of building product development, without losing quality

In the building technology sector, cost control isn’t optional, it’s critical. Product decisions affect not just manufacturing budgets, but also shipping, installation, and long-term performance in harsh environments.

At MMID, we help clients reduce product cost in a way that makes sense for production, the installer, and the end-user. Our integrated development method connects functional requirements with manufacturability and real-life usage, right from the start. Whether you’re working on air distribution components, mounting systems, smart building elements, or plumbing hardware, we design with the full picture in mind.

Reducing cost across the full product lifecycle

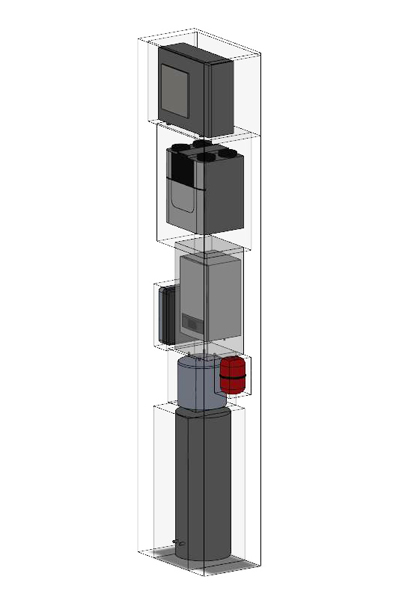

Clear architecture, lower risk

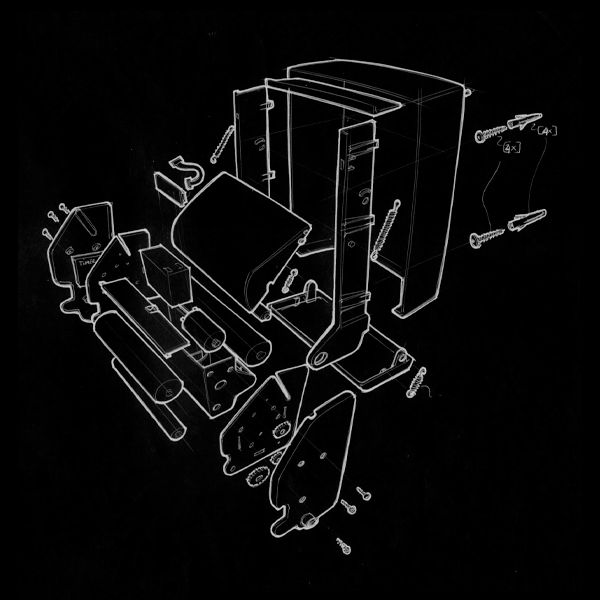

A smart product architecture prevents complexity from creeping in. By deciding early how parts connect and where tolerances matter, MMID can avoid costly iterations during validation and production prep.

“The earlier we define the structure and its functions, the cheaper it is to optimize later”

– Eric van der Voort, Senior Designer Producibility & Assembly

Supplier-ready design from day one

MMID ensures that designs are aligned with supplier capabilities early in the project. Through close collaboration, we avoid design choices that “look good on paper but fail on the line.” In one project, this led to reusing an existing injection molding tool, saving weeks in lead time and thousands in tooling.

“We don’t just throw a design over the wall, we talk with suppliers to make sure the product can actually be made efficiently”

– Bastiaan Soltesz, Specialist Designer Look & Feel

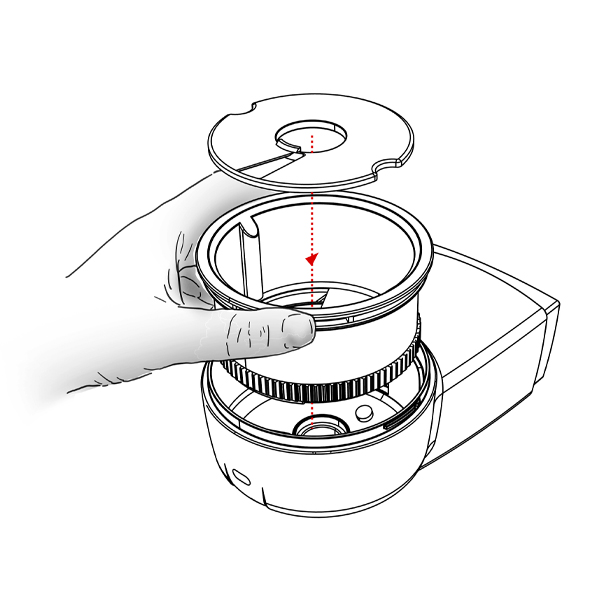

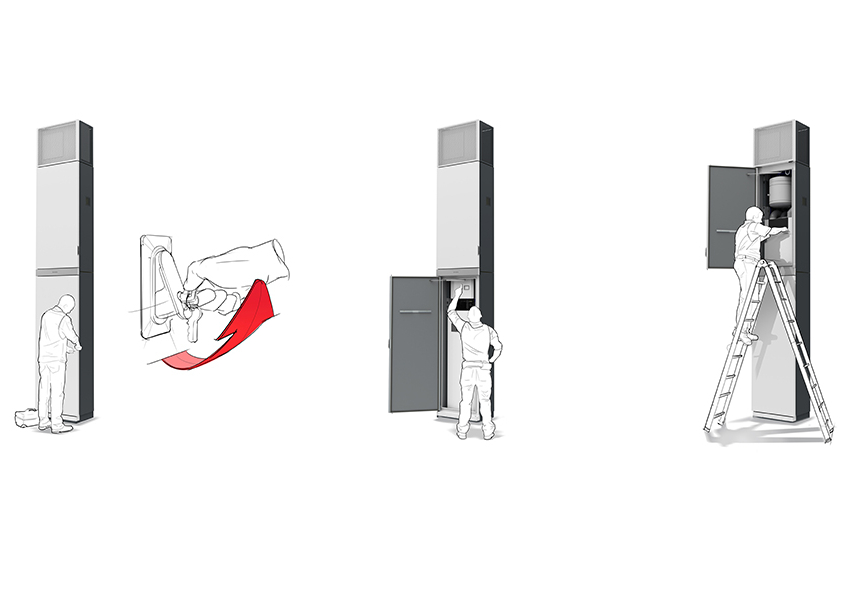

Eliminating unnecessary tooling and rework

A nice example of cost reduction is this smart detail from a building tech project: by slightly rotating a component during early design, the team was able to avoid a costly custom fixture and simplify mounting. Keeping in mind not only the installation and end-user is something that MMID embeds from the start, not as an afterthought late in the process.

“That one small change meant faster installation, no custom tools, and one less thing to source. It just worked”

– Marcel Plug, Senior Designer Look & Feel

Swipe to see the needed tools before and after

Aligning cost, function, and user value

In MMID’s function analysis sessions we prioritize features based on actual user benefit and business impact. These sessions often reveal redundant complexity that can be removed without compromising performance.

“Most of the time, high cost doesn’t come from one thing, it’s a mix of small decisions. We help our clients untangle those”

– Kasper van der Wiel, Specialist Designer Functionality & Systems

Cost isn’t just production, it’s ownership

In many building systems, the long-term costs of maintenance, assembly on-site, or inefficient packaging can easily surpass production costs. MMID actively includes transport, user workflow, and maintenance in the cost equation, reducing hidden costs before they appear.

“A cheaper design that takes longer to install or breaks more often is not cheaper in the long run”

– Stefan Klocke, Designer Producibility & Assembly

Our integrated approach to cost control

In building technology projects, every design decision affects production, logistics, and installation. That’s why MMID embeds cost control into the entire process, not just the final detailing.

-> Supplier-informed design choices

-> Simplified part structures and smart materials

-> Prototyping to test mounting, durability, and use

-> Functionality analysis to remove unnecessary features

-> Consideration of packaging, shipping, and service

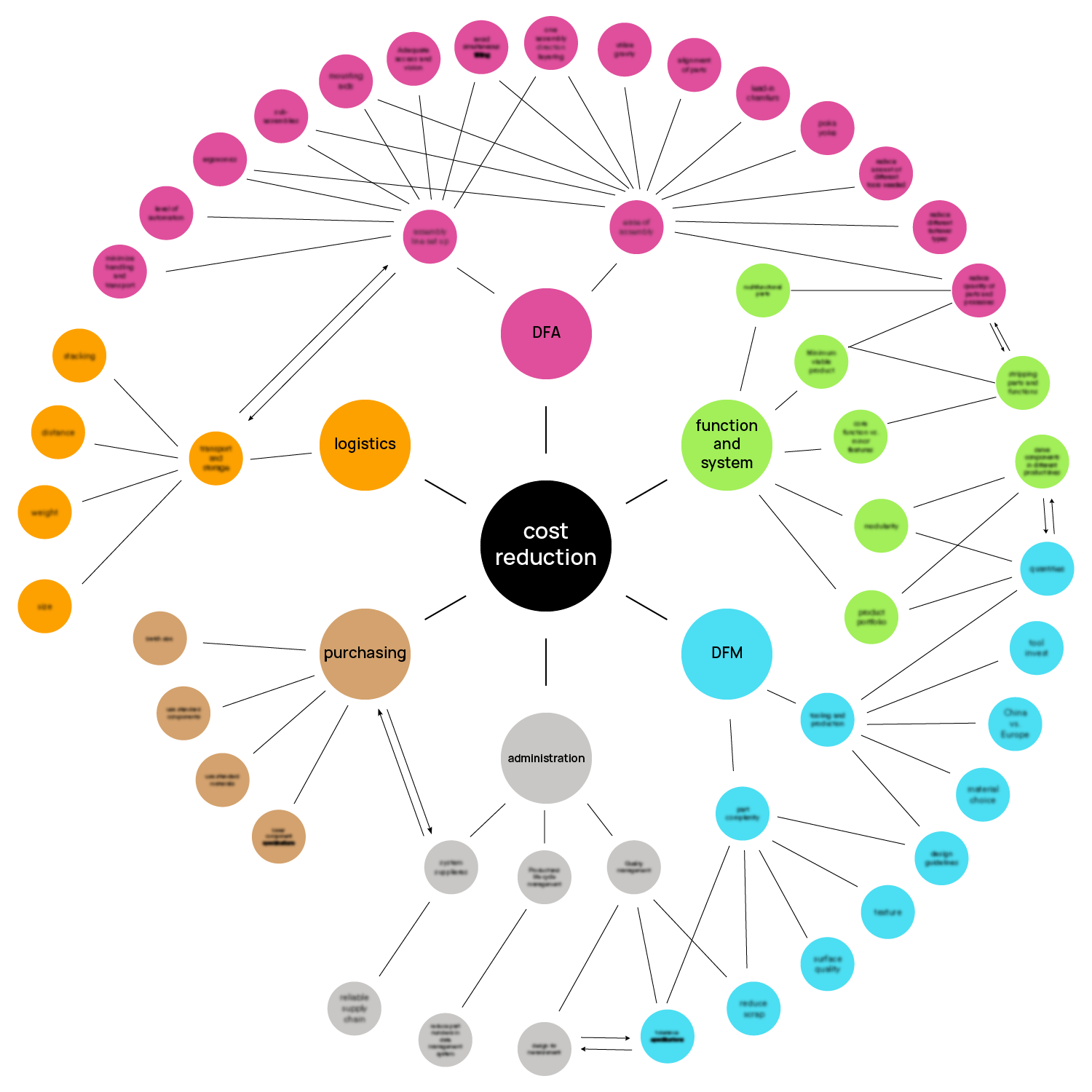

Our development map: how we manage cost from day one

To keep product development on track, technically and financially, we use an internal framework that maps where key cost decisions are made during the process. This system helps avoid surprises, clarify design intentions, and reduce wasted budget and time.

We’ve shared a simplified version below. Some elements are confidential, but the structure shows how we think and how we deliver.

Why clients choose us

✅ Shorter production lead times

✅ Better supplier alignment

✅ Easier installation on-site

✅ Lower long-term cost of ownership

✅ High-performance products with lean construction