Cost reduction in product development

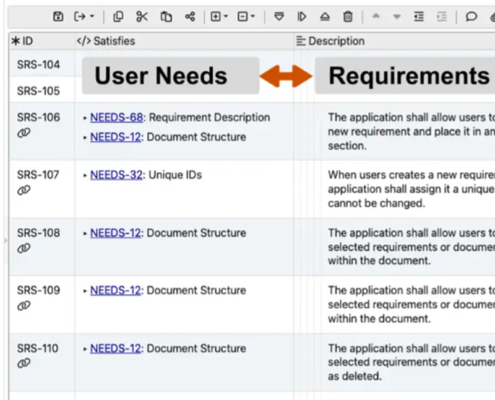

In product development, cost control is often treated as a final step, something to address once the design is done. But by that point, most of the cost is already locked in.

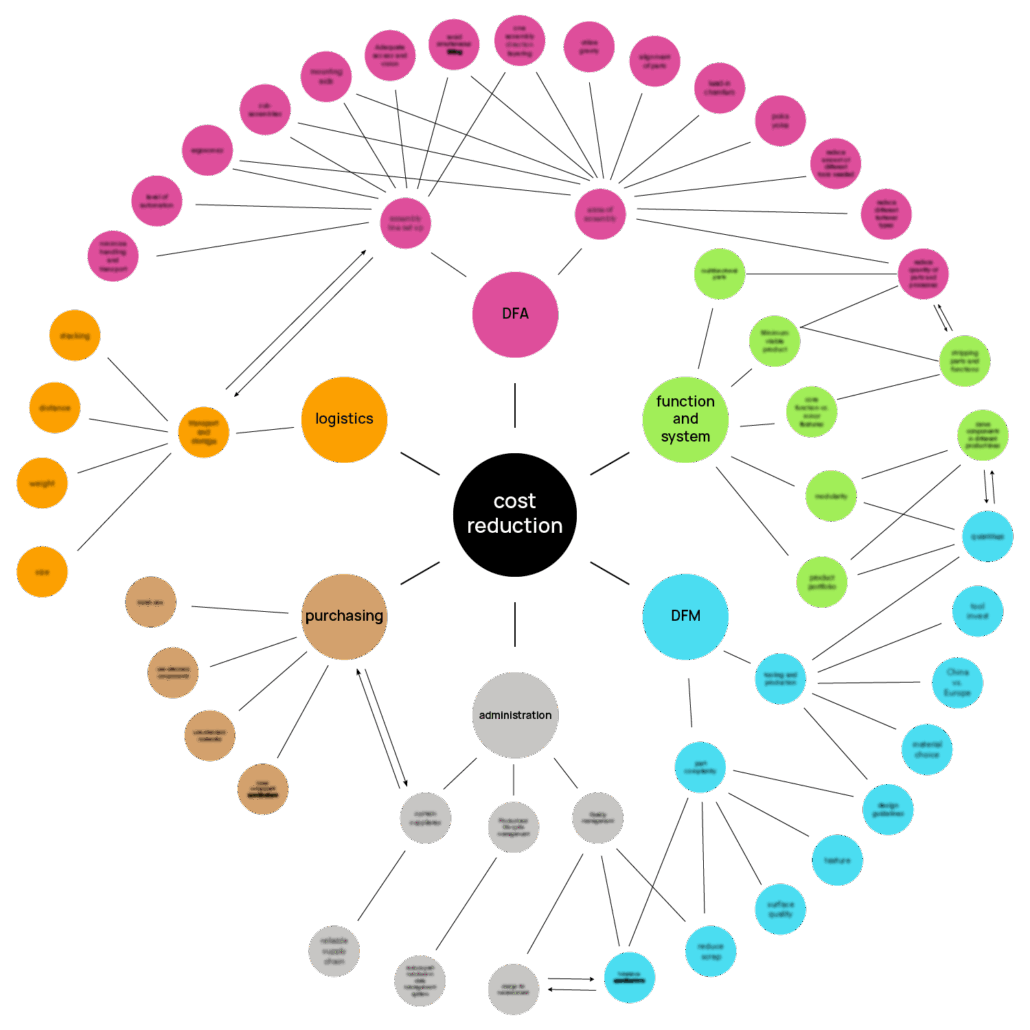

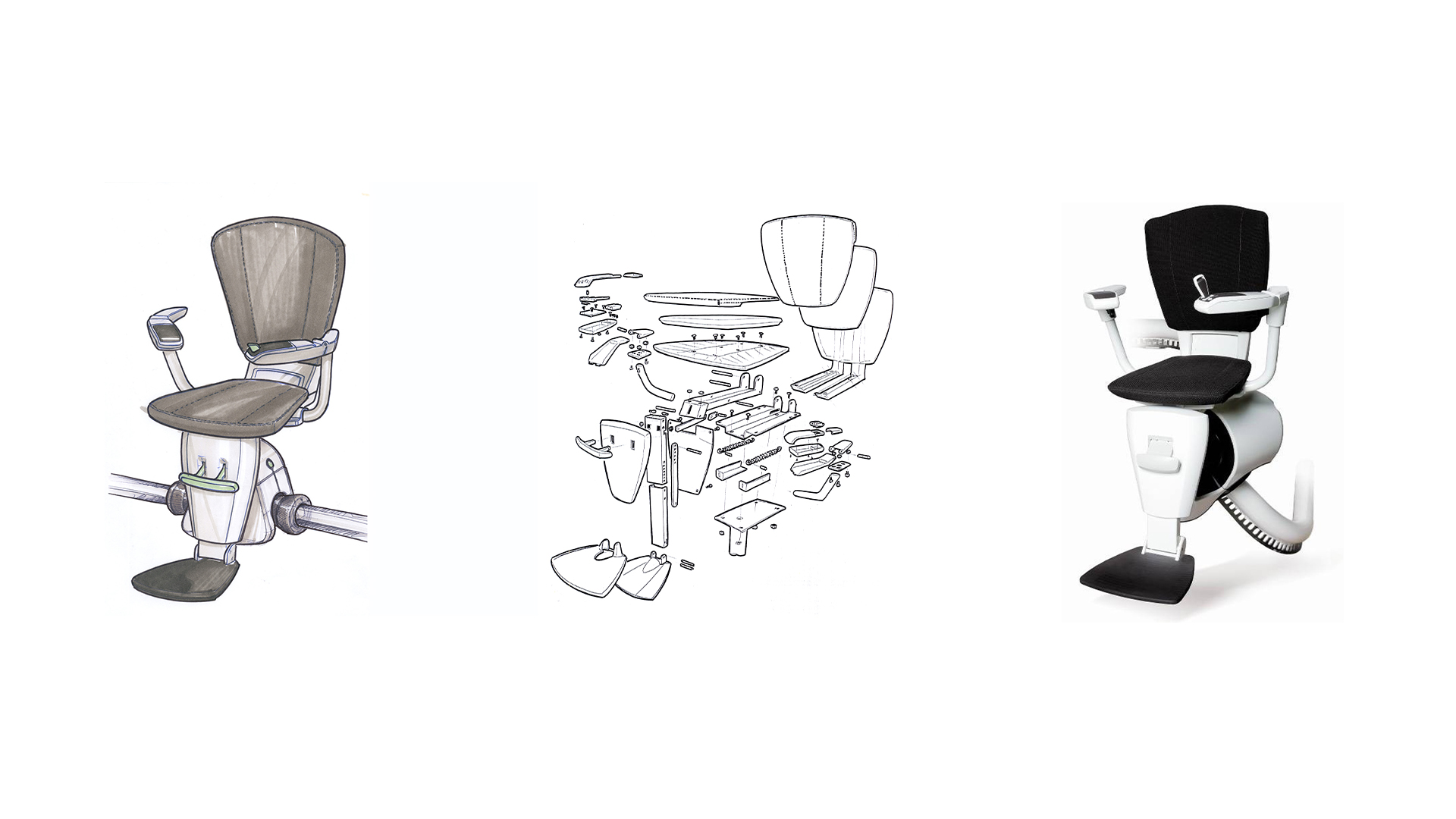

At MMID, we believe cost reduction is a design decision. It begins with how we structure the product, define functions, and plan for production. We help our clients reduce costs without compromising performance, by making smart, system-level decisions early in the process.

From manufacturing and assembly to compliance, logistics, and long-term ownership, the earlier you address cost, the more control you have.