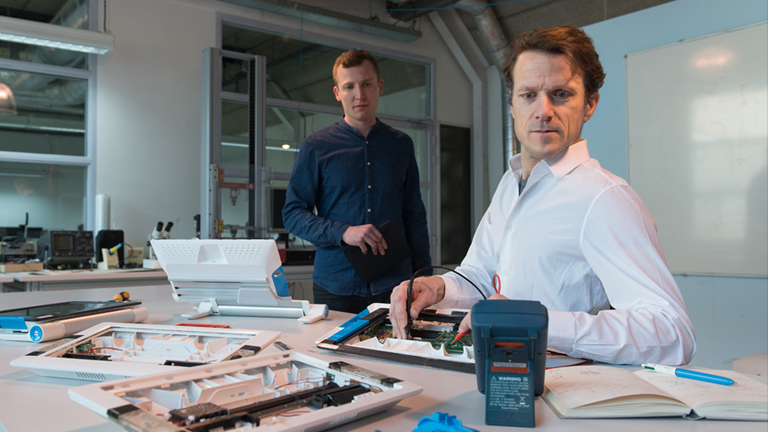

Who are you and how did you end up at MMID?

I am Oscar Toetenel and I am working at MMID for quite some time now, almost 19 years. First, I studied Industrial Design Engineering at TU Delft. I remember that one of my study friends worked at MMID and because of him I went for an open application. It took some kind of detour, but in the end, I got the job! For the first years, I have been a Functionality designer, after this, I have been Discipline Leader for a while, where I coordinated and reviewed our Functionality Discipline. Currently, I am back at being a Functionality and System designer, specialist and competence responsible.

When people ask you what kind of job you do, what do you answer?

I usually say that I am a product developer and that my main focus is on understanding and controlling the physics of our products: Functionality! I make sure that products perform well with physics as a basis; that they move the way they should, that they sound like they should sound and that they are waterproof or that they can handle the required loads for example. I try to understand and apply the proper technical principles, the knowledge from the team, with the aim to design a reliable product that is appreciated by the user.

What is your specialty?

My specialty is to understand and predict behavior of a product or mechanism before – and after – we make it. I’ll find out exactly what handles we can turn and how far those handles can be turned to control the performance. By understanding relations and typical pitfalls, adaptations can be made targeted. Analyzing, modelling, and testing will help us gain more knowledge about the desired effects and the physical boundaries. By understanding what is feasible, we can change and design to improve the concept. As an example: if the product makes an unwanted sound, I will find out what the source is, list the typical measures that apply, and propose the most effective and efficient solution. What I find exciting about this, is that the devil is often in the details; tiny aspects being crucial for having a perfect sustainable and long-lasting product … or not. Finding the parameter that works in an elegant way is very rewarding.

Besides that, what do you like the most about working at MMID?

The thing is; I am always excited to go to work. I can’t remember the last day that I wasn’t. This is at least one thing I cherish about my job. The challenge of improving meaningful products and knowing that I have talented colleagues to rely on.

What I like about MMID is that we have the space to join forces with the client and in our team, that we keep learning from each other and that we’re challenged to do even better. With my colleagues being skilled so differently, you experience what working together brings extra. I could never come that far on my own. The projects are super diverse, yet the LUCID method we use as a team can always be applied. Together we make serious impactful and efficient products on a high-quality level, and that is what I like.

What does your average workday look like?

About one-third of it is meetings with colleagues or clients, then the next one-third is designing solutions and the last one-third is evaluating solutions. As mentioned before, I like the ‘solving the problem’ part the most, this is what keeps me busy in my head. However, this can also be misleading when you want to do it ‘the best way possible’, usually ‘the best way’ is too subjective or impossible in another way (cost). Say for example that you must find the ‘perfect balance’ for a product regarding strength and lightweight… What is perfect for who? There actually is no such thing as perfect, but by reviewing and optimizing together with the team and the client we can come to an optimum.

Can you explain this by one of the projects you did, and what made you most proud?

For me, the Dräger T500 incubator is one of the best projects. It made me realize how important it is to work on quality. The high-quality standards that they have in medical environments are there for a reason; it literally will save lives. Working with these high standards is a challenge and finding solutions that work is very rewarding. Looking at the incubator, I am very proud of MMID for taking part in this development, since we delivered serious insights and results that all came together in this life-saving product.

Another project I had to think about was a roof box clamp for cars I worked on with the team. Whenever I am on a holiday with my family and I am driving through France, I see them everywhere, knowing that those people could take everything they wanted because of our effort. Reminding me also that an idea can come from all corners, and that changing perspective sometimes reveals new solutions.

What do you do next to MMID?

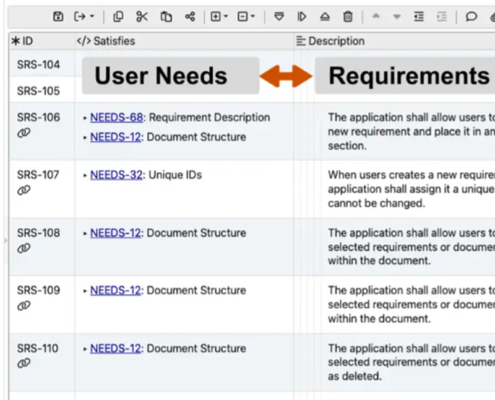

Spending time with my kids and wife, sometimes (but not enough) I am in my community garden, or I do some sports such as bouldering and climbing. Next to that, I like to learn more every day which makes me excited. Since recently I am quite enthusiastic about requirements management, keep in touch with our LinkedIn to know more about that!

If you describe MMID in three words, what would it be?

“Diverse, challenging, teamwork”.

Why those three words?

Diverse: Because of the broad customer portfolio we have with many different products. Together we have a wide range of knowledge taking all previous projects into account. The areas can differ from water, air, electricity, medical, packaging, coffee to plants and much more. These different areas provide a lot of knowledge that we gained over the years and help cross-pollination.

Challenging: There is always something new to master. The bar is set high when designing new products, it triggers us to find the best product solutions and to find the best in ourselves. We are always looking for better ways to deliver the expected quality with a systematic approach. So, we are challenged in the way of working and try to outsmart the competition. Because in the end, we do want to deliver the best product solution on the market.

Teamwork: What I can do alone is nothing compared to what I can do with the MMID team. It’s our distributed memory; all the knowledge and experience, recombining in such great products and having joy. On my own, I would never be able to do something like this. You need people with different perspectives and dedication to a shared goal.